Build the scale 1:1 mock-up

A friend of mine had a big size filament 3D printer, which did not worked well.

He asked me to fix it, so I had the opportunity to use it for my stuff.

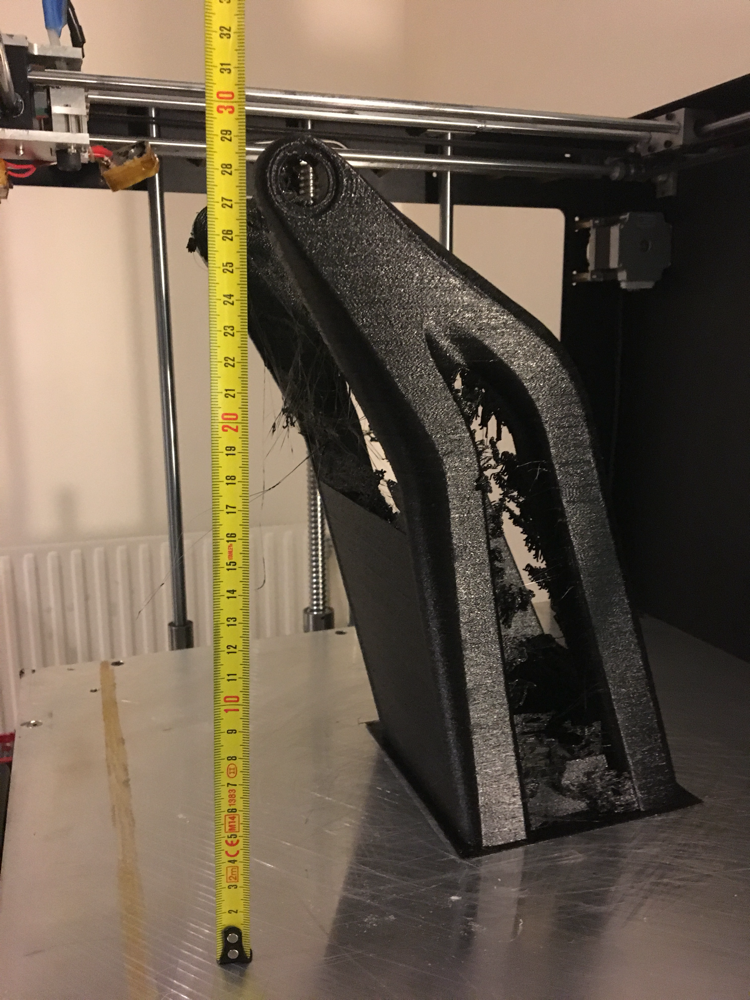

Once I got it fixed, I cut the CAD in multiple pieces, and started the prints for the front triangle. Then every parts were bonded together with epoxy.

I did the exact same thing for he swingarm, in only two big pieces

I machined the pivots inserts on a lathe, and then checked the assembly of these pivots, the rear axle and derailleur hanger, and the BB insert.

To simulate the shock I just used two pieces of plastic tube sliding one in the other set to the correct shock stroke.

I put all these components together and was then ready to check the final result.

January 2017, I was ready to build the bike with all the components.

This step allow to check clearance between the components, which is more than necessary

At this step of the project, I could not stop.

I had some idea to make the bike real, but I am not a composites expert, and I needed to decide the tooling process.

Click here to see how I did it